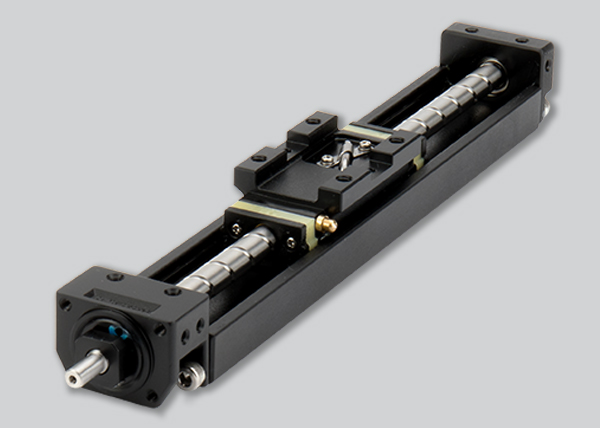

Linear ball slide is a critical component in various fields, providing as smooth and accurate linear motion as possible. Their productivity and precision make them absolutely indispensable in quite a number of applications.

1. Industrial Automation

- Enables precise movement of the robotic arms and pick-and-place systems.

- Precision and repetition of automated processes

- Material handling and assembly lines.

2. CNC Machines and Machining Centres

- Allows sharp cutting, milling, and drilling. Keywords

- Facilitates high speed machining with high accuracy as well as low vibration motion.

3. Semiconductor Manufacturing

- Necessary for wafer handling, lithography, and microfabrication.

- Must ensure precision in critical process steps of sub-microns.

4. Medical Devices

- Used in imaging systems, such as CT and MRI scanners.

- Enhances reliability in robotic surgery and lab automation.

5. Packaging and Printing Industry

- Supports high-speed labelling, sealing, and filling operations.

- Precise motion for print head movement in inkjet and screen-printing operations.

6. 3D Printing and Additive Manufacturing

- Offers accurate layer-to-layer motion for reliable 3D printing.

- Used in Large Format and High-Resolution Printers

7. Aerospace and Defence

- Installed in testing rigs for aerodynamic modelling

- Also utilized during the assembly of satellite components and other critical applications.

8. Textile and Garment Industry

- Scaffold Automatic Stitching, Embroidery, and Fabric inspection.

9. Laboratory and Research Equipment

- Sustain motion in spectrometry and measurement devices with high precision.

10. Automotive Manufacturing

- Used in car manufacturing assembly lines as well as testing equipment.

Comparison of Linear Ball Slides with Other Linear Motion Systems

The Linear ball slide, Linear motors, and Roller bearings are some of the key motion systems showing individual strengths. Ball slides have high precision, smooth motion, and moderate load-carrying capability. They are used in CNC machines and medical equipment. Linear motors set an absolutely unprecedented record in rates and precision but are more expensive, so their application is more likely to occur in semiconductors and robotics. Roller bearings provide the best rating in terms of loads and lower precision and are suited for heavy industry machinery. In comparison with other slides, Linear ball slide is balanced between cost-effectiveness and precision.

Linear ball slide has perfectly smooth, precise motion, which is particularly what is required in applications that are accurate and reliable. In many instances, they also entail lower friction levels and, thus, cause less wear and lower energy consumption; besides all this, compact designs save space. Linear ball slide is cost-efficient, robust, and versatile, hence suitable for the automation industry, CNC machining, or equipment in medical devices.